Cold Lamination vs Hot Lamination: Complete Guide for Print Shops in 2025 Leave a comment

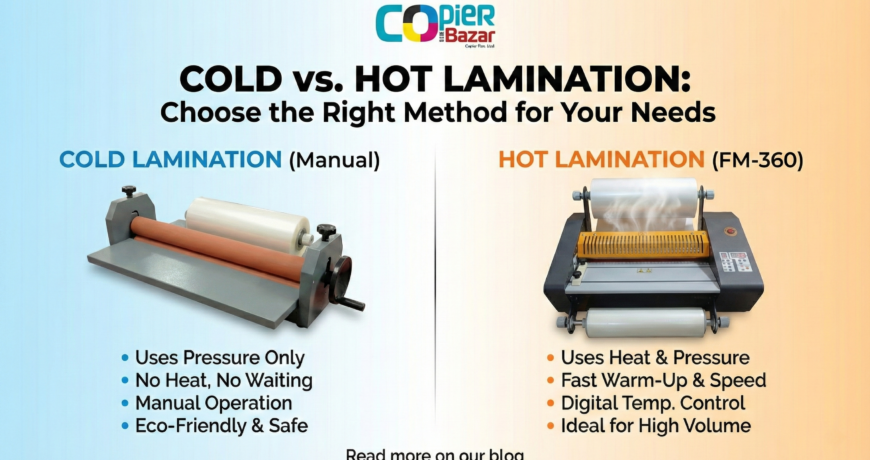

Choosing the right lamination method can make or break your print finishing business. Whether you’re running a print shop, advertising agency, or photography studio in India, understanding the difference between cold lamination and hot lamination is crucial for delivering quality results and maximizing your investment.

In this comprehensive guide, we’ll explore both lamination techniques, compare their advantages and disadvantages, and help you decide which method suits your business

lneeds in 2025.

Table of Contents

What is Cold Lamination?

Cold lamination is a pressure-sensitive laminating process that bonds protective film to printed materials without using heat. Instead of thermal activation, cold lamination relies on adhesive-backed films that stick to your prints through pressure applied by rollers.

How Cold Lamination Works

The cold lamination process is straightforward:

- Film Loading: A roll of pressure-sensitive lamination film is loaded onto the machine

- Material Positioning: Your printed material is aligned with the adhesive film

- Pressure Application: The material passes through precision rollers that apply even pressure

- Bonding: The adhesive on the film bonds to the print surface without heat

- Trimming: Excess film is trimmed to complete the lamination

Key Characteristics of Cold Lamination

No Heat Required: The biggest advantage of cold lamination is that it operates at room temperature, making it safe for heat-sensitive materials.

Manual or Electric Options: Cold lamination machines come in both manual hand-crank models and electric motorized versions, giving you flexibility based on volume and budget.

Pressure-Sensitive Adhesive: Uses self-adhesive films that activate through pressure rather than heat, ensuring compatibility with various substrates.

Lower Operating Costs: Without heating elements, cold laminators consume less electricity and have fewer mechanical components that can fail.

What is Hot Lamination?

Hot lamination, also known as thermal lamination, is a process that uses heat and pressure to bond protective film to printed materials. The lamination film contains a heat-activated adhesive that melts and flows onto the substrate when heated.

How Hot Lamination Works

The hot lamination process involves:

- Heating: The laminator heats up to the required temperature (typically 100-140°C)

- Film Threading: Pre-coated thermal film is loaded into the machine

- Material Feeding: Printed material is fed into the heated rollers

- Thermal Bonding: Heat activates the adhesive, which bonds permanently to the print

- Cooling: The laminated material cools and the bond solidifies

- Finishing: The laminated print exits ready for trimming

Key Characteristics of Hot Lamination

Heat-Activated Bonding: Uses thermal films with adhesive that requires specific temperatures to activate and create a permanent bond.

Permanent Seal: Creates a stronger, more permanent bond compared to cold lamination, ideal for items requiring long-term durability.

Faster Production: Once heated, hot laminators can process materials more quickly, making them suitable for high-volume operations.

Professional Finish: Typically produces a clearer, more professional appearance with better optical clarity.

Cold Lamination vs Hot Lamination: Key Differences

Here’s a comprehensive comparison to help you understand the critical differences between these two lamination methods:

| Feature | Cold Lamination | Hot Lamination |

|---|---|---|

| Temperature | Room temperature (no heat) | 100-140°C required |

| Activation Method | Pressure-sensitive adhesive | Heat-activated adhesive |

| Warm-Up Time | Instant, ready to use | 3-10 minutes warm-up required |

| Suitable Materials | All materials including heat-sensitive | Heat-resistant materials only |

| Bond Strength | Good, removable options available | Excellent, permanent bond |

| Speed | Moderate (manual models slower) | Fast (once heated) |

| Energy Consumption | Very low (manual: zero) | Higher due to heating element |

| Initial Cost | Lower (₹8,000 – ₹35,000) | Higher (₹25,000 – ₹2,00,000+) |

| Operating Cost | Minimal | Higher (electricity, maintenance) |

| Film Cost | Generally higher per meter | Generally lower per meter |

| Applications | Photos, inkjet prints, vinyl, foam board | Documents, posters, signage, menus |

| Finish Quality | Good, slight texture possible | Excellent, crystal clear |

| Maintenance | Minimal | Regular cleaning, calibration |

| Portability | High (manual models) | Low (requires power) |

| Skill Level | Easy to learn | Requires temperature control knowledge |

When to Use Cold Lamination

Cold lamination is the ideal choice for specific applications and business scenarios:

Best Applications for Cold Lamination

Heat-Sensitive Materials

- Inkjet prints (water-based inks can run with heat)

- Thermal papers and receipts

- Photographs printed on heat-sensitive paper

- Vinyl graphics and decals

- Foam board mounting

Large Format Graphics

- Banners and posters over 24 inches wide

- Point-of-sale displays

- Trade show graphics

- Wall murals and wallpaper

- Vehicle wraps and graphics

Specialty Applications

- Canvas prints and fine art reproduction

- Fabric printing lamination

- Self-adhesive sticker production

- Temporary signage and displays

- Digital prints on coated papers

Business Scenarios Favoring Cold Lamination

Starting a Print Business: If you’re launching a print shop with limited budget, manual cold lamination machines offer an affordable entry point without sacrificing quality.

Mobile or On-Site Services: Cold laminators, especially manual models, are portable and don’t require electricity, making them perfect for events, exhibitions, or mobile printing services.

Photography Studios: Professional photographers working with fine art prints and canvas need cold lamination to protect their work without risking heat damage.

Low-Volume Operations: For businesses handling moderate lamination volumes, the simplicity and low operating costs of cold lamination make financial sense.

Versatile Material Handling: If your business works with diverse substrates including heat-sensitive materials, cold lamination provides the flexibility you need.

When to Use Hot Lamination

Hot lamination excels in different scenarios and applications:

Best Applications for Hot Lamination

High-Volume Documents

- ID cards and badges

- Restaurant menus and price lists

- Educational materials and flashcards

- Business cards and loyalty cards

- Certificates and awards

Professional Signage

- Outdoor signage requiring weather resistance

- Retail displays and shelf talkers

- Product labels and tags

- Door and window graphics

- Permanent wayfinding signage

Commercial Printing

- Book covers and dust jackets

- Magazine covers

- Brochures and catalogs

- Packaging materials

- Marketing collateral

Business Scenarios Favoring Hot Lamination

High-Volume Print Shops: Established print centers processing hundreds of lamination jobs daily benefit from the speed and efficiency of hot lamination.

Document Service Providers: Businesses specializing in ID cards, menus, and document protection require the permanent bonding and durability of hot lamination.

Commercial Printers: Professional printing companies producing marketing materials and publications need the superior finish quality of thermal lamination.

Outdoor Signage Businesses: Companies creating weather-resistant outdoor signage require the stronger, permanent bond that hot lamination provides.

Cost-Per-Unit Focus: For very high volumes, hot lamination’s lower film costs can result in better per-unit economics despite higher initial investment.

Cost Comparison: Cold vs Hot Lamination

Understanding the total cost of ownership helps make an informed decision:

Initial Investment

Cold Lamination Machines:

- Manual 650mm (25 inch): ₹8,000 – ₹15,000

- Manual 750mm (30 inch): ₹12,000 – ₹20,000

- Electric 650mm: ₹18,000 – ₹35,000

- Electric 1000mm+: ₹40,000 – ₹80,000

Hot Lamination Machines:

- Desktop A4 size: ₹12,000 – ₹25,000

- Professional A3 size: ₹25,000 – ₹60,000

- Wide format 650mm: ₹60,000 – ₹1,50,000

- Industrial models: ₹2,00,000 – ₹10,00,000+

Operating Costs

Cold Lamination:

- Film cost: ₹3-8 per linear foot (depending on width and finish)

- Electricity: ₹0 (manual) or minimal (electric)

- Maintenance: Very low (occasional roller cleaning)

- Monthly operating cost (100 jobs): ₹3,000 – ₹8,000

Hot Lamination:

- Film cost: ₹2-5 per linear foot

- Electricity: ₹500 – ₹2,000 per month (depending on usage)

- Maintenance: Regular cleaning, temperature calibration

- Monthly operating cost (100 jobs): ₹4,000 – ₹12,000

Break-Even Analysis

For a typical print shop in India:

Low Volume (50-100 laminations/month): Cold lamination offers better ROI due to lower initial investment and operating costs.

Medium Volume (200-500 laminations/month): Consider electric cold lamination or entry-level hot lamination based on material types.

High Volume (1000+ laminations/month): Hot lamination becomes cost-effective due to faster processing and lower film costs per unit.

Choosing the Right Lamination Machine for Your Business

Here’s a practical decision framework:

Choose Cold Lamination If You:

- Work primarily with heat-sensitive materials (photos, inkjet prints, vinyl)

- Have budget constraints (starting under ₹20,000)

- Need portability or work without consistent power supply

- Process low to medium volumes (under 200 laminations/month)

- Require flexibility with various material types and thicknesses

- Prefer lower monthly operating costs

- Are starting a new print business or side venture

Choose Hot Lamination If You:

- Focus on documents, menus, and ID cards requiring permanent protection

- Process high volumes daily (500+ laminations/month)

- Need the fastest possible production speed

- Work with standard paper materials that tolerate heat

- Require the clearest, most professional finish quality

- Have established business with steady cash flow for investment

- Specialize in outdoor signage or weather-resistant applications

Consider Both If You:

- Run a full-service print shop handling diverse projects

- Want to offer comprehensive finishing services

- Work with both heat-sensitive and standard materials

- Can invest in building a complete finishing department

- Serve clients with varying quality and budget requirements

Equipment Recommendations from CopierBazar

Based on 20+ years of serving print shops across India, here are our top recommendations:

For Cold Lamination

Best for Startups: 650mm Manual Cold Lamination Machine Perfect for new print shops and photography studios. Our 650mm (25 inch) manual cold laminator handles most standard poster and banner sizes without electricity costs. Ideal for businesses processing 50-150 laminations per month.

View 650mm Cold Lamination Machine →

Key Features:

- 650mm working width (handles A2 size and 24-inch posters)

- Heavy-duty steel construction

- Adjustable tension control for bubble-free results

- No electricity required

- Compact footprint

- Investment: ₹12,999

Best for Growing Businesses: 750mm Manual Cold Lamination Machine For businesses handling larger format graphics and higher volumes. The 750mm (30 inch) width accommodates most commercial printing needs including banners, retail displays, and photography work.

View 750mm Cold Lamination Machine →

Key Features:

- 750mm working width (handles 30-inch materials)

- Professional-grade rollers for consistent pressure

- Suitable for materials up to 3mm thick

- Manual operation with ergonomic hand-crank

- Investment: ₹18,999

Film Recommendations

Cold Lamination Films Available:

- Glossy finish (enhances colors and vibrancy)

- Matte finish (reduces glare, professional look)

- Semi-gloss (balanced appearance)

- UV-resistant (outdoor applications)

- Removable adhesive (temporary applications)

Available widths: 610mm (24″), 760mm (30″), 914mm (36″), 1270mm (50″)

Browse Cold Lamination Films →

Installation and Support

What’s Included with Your Purchase:

- Free pan-India shipping on orders above ₹5,000

- Video installation tutorials in English and Hindi

- Phone and WhatsApp support for setup

- Operation manual with troubleshooting guide

- 30-day return policy

Training and Support:

- Free consultation to choose the right machine

- Setup assistance via video call

- Ongoing technical support

- Film recommendation based on your applications

Can I use hot lamination film in a cold laminator?

No, hot lamination film requires heat to activate the adhesive and will not bond properly in a cold laminator. Similarly, cold lamination film is pressure-sensitive and doesn’t require heat. Always use the appropriate film type for your machine.

Which lamination method lasts longer?

Hot lamination typically creates a more permanent, durable bond that’s ideal for items requiring long-term protection like ID cards and outdoor signage. Cold lamination provides excellent protection but can be formulated as removable for temporary applications. For maximum longevity, hot lamination is superior.

Is cold lamination suitable for outdoor banners?

Yes, when used with UV-resistant cold lamination film, it’s excellent for outdoor applications. Cold lamination doesn’t stress heat-sensitive banner materials and provides protection from weather, UV rays, and physical wear. Many professional signage companies prefer cold lamination for large format outdoor graphics.

How much electricity does a hot laminator consume?

A typical 650mm hot laminator consumes 1.5-2 kW during operation. For a print shop running 6 hours daily, expect monthly electricity costs of ₹1,500-₹2,500 depending on your local rates. Cold manual laminators consume zero electricity.

Can I laminate photographs with hot lamination?

It depends on the photograph type. Digital prints on heat-resistant photo paper can be hot laminated safely at lower temperatures (around 100°C). However, instant photos, inkjet prints on regular paper, and some professional photo papers are heat-sensitive and require cold lamination to prevent discoloration or melting.

What causes bubbles in lamination and how do I prevent them?

Bubbles occur due to trapped air, dust, uneven pressure, or incorrect temperature (in hot lamination). Prevention tips:

Clean your material and rollers thoroughly before laminating

Ensure even roller pressure across the width

Use appropriate temperature settings for hot lamination

Feed material straight and steady

For cold lamination, use slow, consistent pressure

Remove static from materials before laminating

Which is better for vehicle wraps: cold or hot lamination?

Cold lamination is the industry standard for vehicle wraps. Heat can damage vinyl graphics and cause stretching or distortion. Cold lamination preserves the dimensional accuracy of cut graphics and provides UV protection without risking material damage. Use automotive-grade cold lamination films for best results.

How do I maintain my cold lamination machine? Cold lamination machines require minimal maintenance:

Clean rollers weekly with isopropyl alcohol to remove adhesive residue

Check roller alignment monthly to ensure even pressure

Lubricate moving parts every 3-6 months (manual models)

Inspect film guides for wear and alignment

Store in a dry environment to prevent rust

Cover when not in use to keep dust away

What’s the difference between 1-sided and 2-sided lamination?

1-sided (single-sided) lamination applies film to one surface only, commonly used for mounting prints to boards or protecting one side. 2-sided (double-sided) lamination encapsulates material between two film layers, providing complete protection. Most desktop cold laminators are single-sided; for double-sided, you need to run the material through twice or use a specialized machine.

Q: How do I calculate lamination costs per job? Calculate lamination costs using this formula:

- Film cost = (Material length × Material width × Film price per sq. foot)

- Labor cost = (Time required × Hourly rate)

- Overhead = (Electricity + Machine depreciation + Maintenance) / Monthly jobs

- Total cost per job = Film cost + Labor cost + Overhead

- Selling price = Total cost × Profit margin (typically 2-3x for commercial work)

Example: A3 poster lamination might cost ₹15 in materials, ₹10 in labor/overhead, selling for ₹50-75 to clients.

Making Your Decision: Next Steps

Now that you understand the differences between cold and hot lamination, it’s time to choose the right equipment for your business.

For Most Print Shops Starting Out:

We recommend beginning with a 650mm manual cold lamination machine. It offers the best balance of affordability, versatility, and zero operating costs. You can handle heat-sensitive materials and most standard formats without the complexity of temperature control.

For Established Businesses:

Consider adding a 750mm cold laminator to handle larger formats and increase production capacity. If you’re processing high volumes of documents and menus, add a hot laminator for those specific applications.

Ready to Get Started?

Contact CopierBazar Today:

- Phone: Available Monday-Saturday, 10 AM – 7 PM IST

- Email: sales@copierbazar.com

- WhatsApp: Get instant quotes and expert advice

- Website: Browse our complete range at CopierBazar.com

Free Consultation: Not sure which laminator suits your needs? Our experts are here to help. With 20+ years of experience serving print shops across India, we’ll guide you to the right choice based on your specific requirements and budget.

Special Offers:

- Free shipping on orders above ₹5,000

- Bulk discounts available on multiple units

- Complete starter packages with machines and films

- 30-day satisfaction guarantee

Transform your print finishing capabilities with the right lamination equipment. Whether you choose cold, hot, or both, CopierBazar has the expertise and products to help your business succeed.